Engineering Components and Precision Tools Made of Tungsten Carbide:

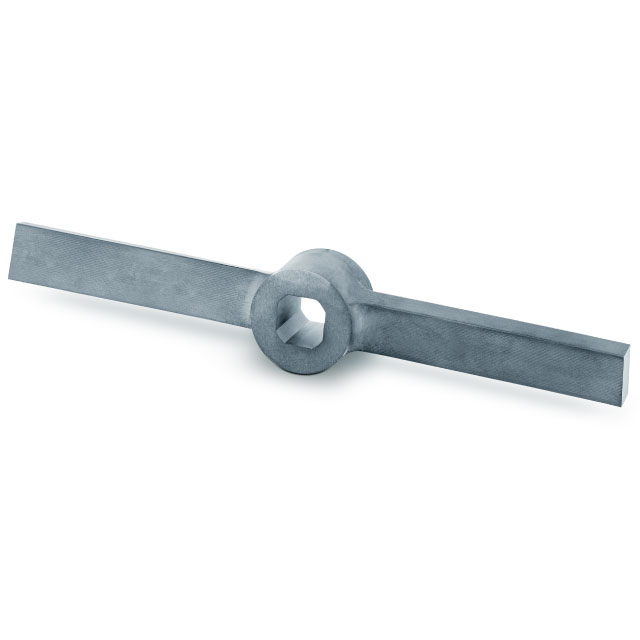

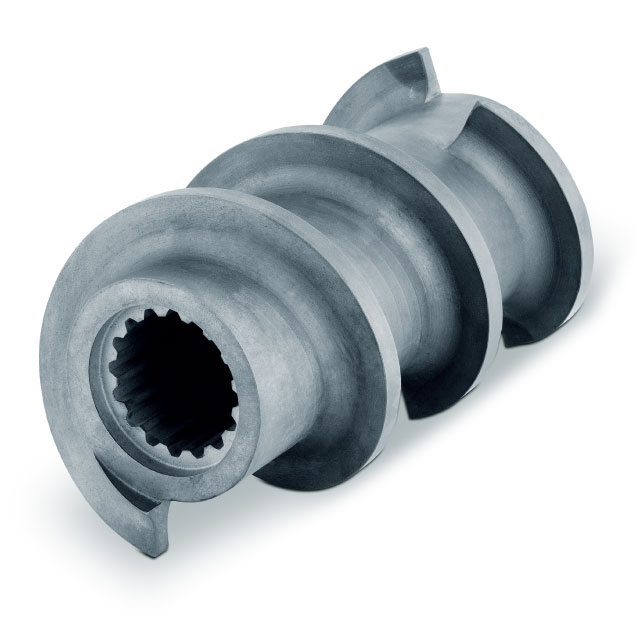

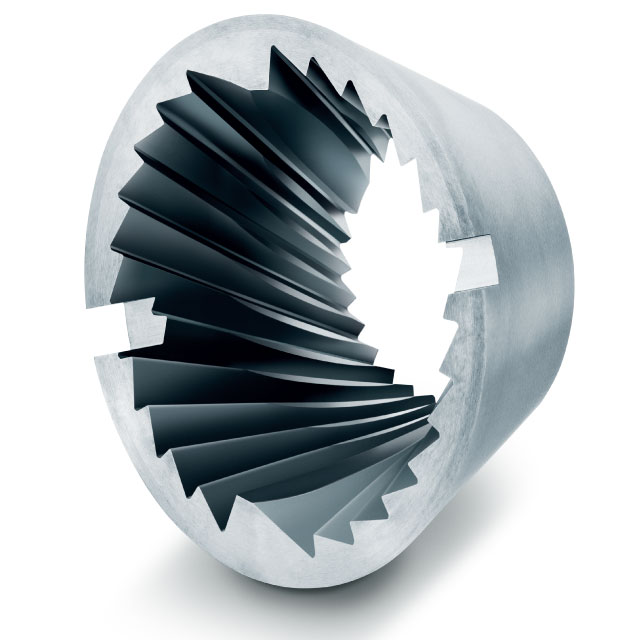

Including but not limited to grinding bowls, grinding rings, grinding stones, grinding pins, grinding discs, grinding cones, impact bars, pestles, crusher rolls, crusher jaws, crusher plates, sieve rings, linings, mandrels, knife bars, scraper bars, sieve inserts, extruder screws, conveyor screws, mixer paddles, inner linings, bearing bushings, perforated plates, screw segments, nozzles, forming rolls, as well as custom components according to customer drawings.

Typical Applications: Pin mills, laboratory mills, conical mills, hammer mills, shredders, pelletizing plants, jaw crushers, impact mills, roll crushers, screw extruders, mixers.

Coatings for All Industries and Applications: THERMAL COATINGS HVOF/APS/EAWS / LASER CLADDING / PVD / CVD

DURIT operates globally across a variety of industries and demanding niche markets, including but not limited to:

Automotive Industry

Forming Technology

Chemical, Petrochemical, and Oil Industries

Pharmaceutical Industry and Medical Technology

Powder Processing Industry

Mechanical Engineering and Plant Construction

And many others

As a modern family-owned company, DURIT has been developing and manufacturing precision tools and construction components made of tungsten carbide for over 35 years. More than 500 employees, including specialists, application engineers, and engineers, are dedicated to optimizing the productivity of their international customers. Together, at locations in Germany, Portugal, and Brazil, they uphold the highest quality standards—ensuring durability and cost-effectiveness for all industries worldwide. Whether standard or custom-made, in series production or single-unit manufacturing: The DURIT range of services includes product solutions precisely tailored to customer needs.