Building on a proven functional principle, the design has been revised to achieve greater separation efficiency, shorter maintenance cycles, and energy-efficient vibration characteristics.

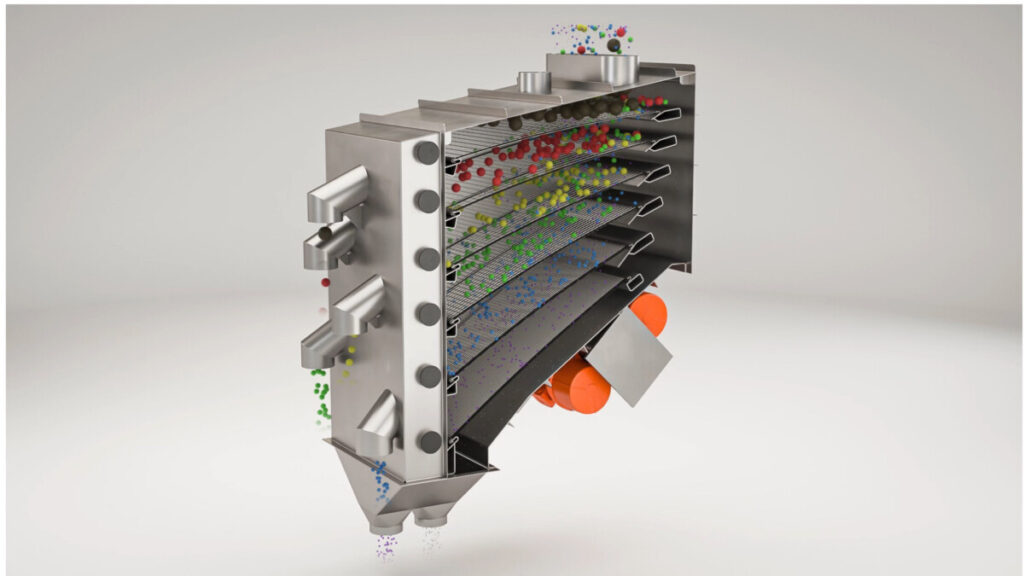

The Multiple Deck Sizer stands for precise layer classification, robust assemblies, short maintenance times, and compact machine geometry.

The aim is to rethink classic screening technology—with higher precision, modular design, and optimized energy efficiency.

Advantages at a glance:

– Precise separation thanks to thin material layer

– Modular deck structure with up to six screening decks

– Service-friendly design with short changeover times

– Energy-efficient vibration mechanism with high throughput

– Compact footprint for integration into existing plants

– FEM-optimized structure for high operational reliability and service life

A major benefit of the Multiple Deck Sizer is its applicability in almost every industry:

– Stone & earth

– Metallurgy

– Animal feed

– Biofuels & pallets

– Food

– Pharmaceuticals

– Plastics

– Chemicals

– Construction materials

– Ceramics

– Waste & recycling

– Mining