To install mechanical fasteners on conveyor belts, we recommend you skive the belt. Skiving reduces the fastener profile on the belt and improves the compatibility of the fastener with the belt cleaner, increasing the service life of this component. Flexco Europe will also present the FSK2MP in Dortmund. This is a handy, lightweight and easy-to-carry belt skiver, which the service technician can adjust to the required skiving depth. The blade is securely enclosed during the work. The FSK2MP can also be used on most worn and damaged belts. The battery-powered skiver is also up to five times faster than manual skiving. Flexco Europe will also showcase a combination tool consisting of a belt cutter and a skiver.

When it comes to mechanical fasteners for conveyor belts, Flexco is the acknowledged specialist. The company will also showcase its innovative solution for steel cord conveyor belts – the Steel Cord fastener range. These belts are often used in systems where long distances or steep gradients necessitate high levels of safety. With this innovative concept, the manufacturer now offers a solution that allows users to fasten belts in only half the time required by existing mechanical systems on the market and roughly one-third of the time needed for vulcanization.

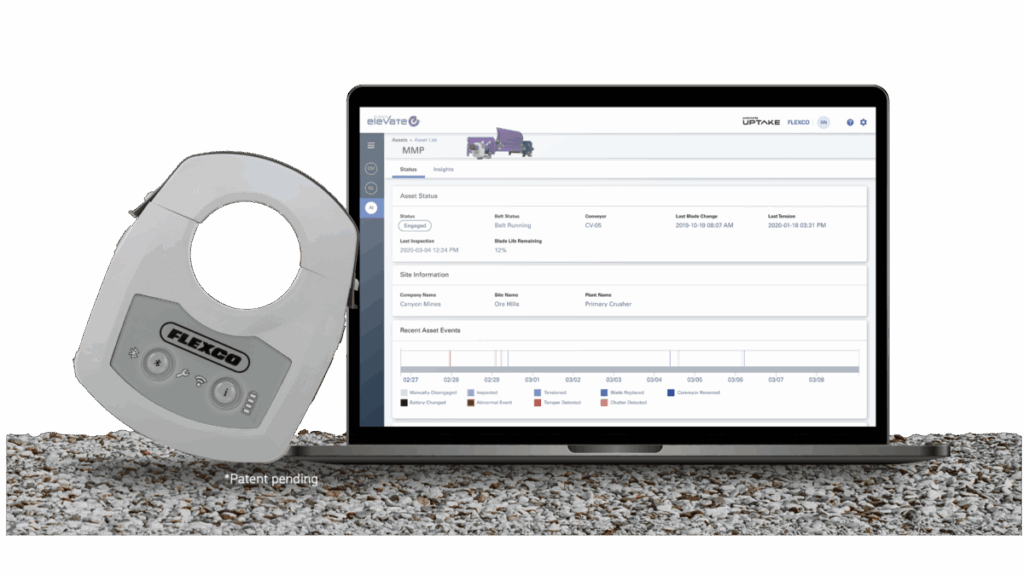

Flexco Europe will also go digital with Elevate, a holistic monitoring system that reduces and even avoids unexpected belt downtime in mines and cement works. The Elevate devices attached to the conveyor belt cleaners collect data that can be retrieved in real time via an app or a dashboard, regardless of location. Installation, commissioning, and monitoring procedures are fast and easy to handle. The obtained data enables operators to make informed decisions and take remedial measures quickly. When a malfunction signal occurs involving a preventive on-site belt inspection, for example, they can rectify the problem at an early stage and not simply react when the failure has already happened.